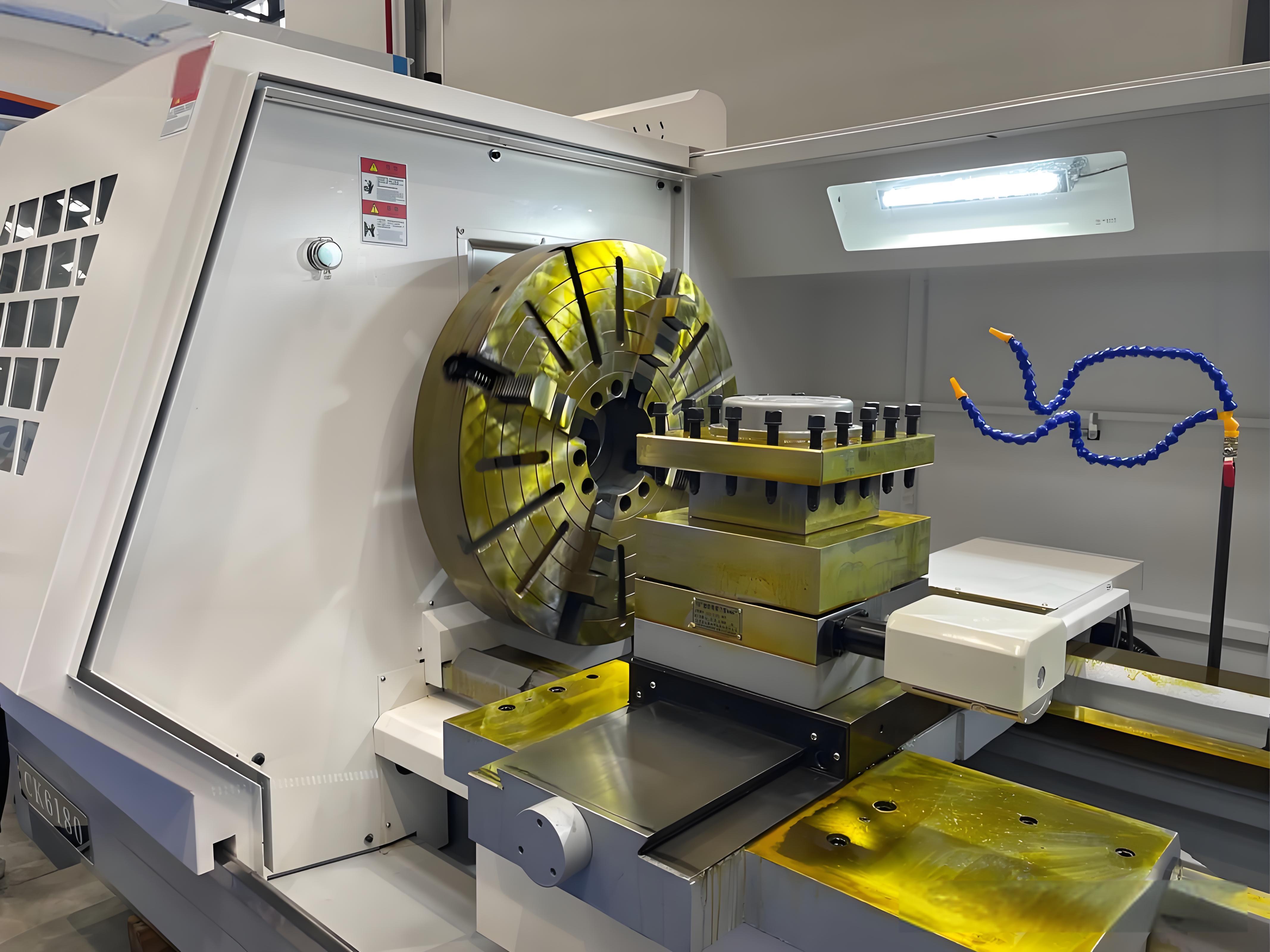

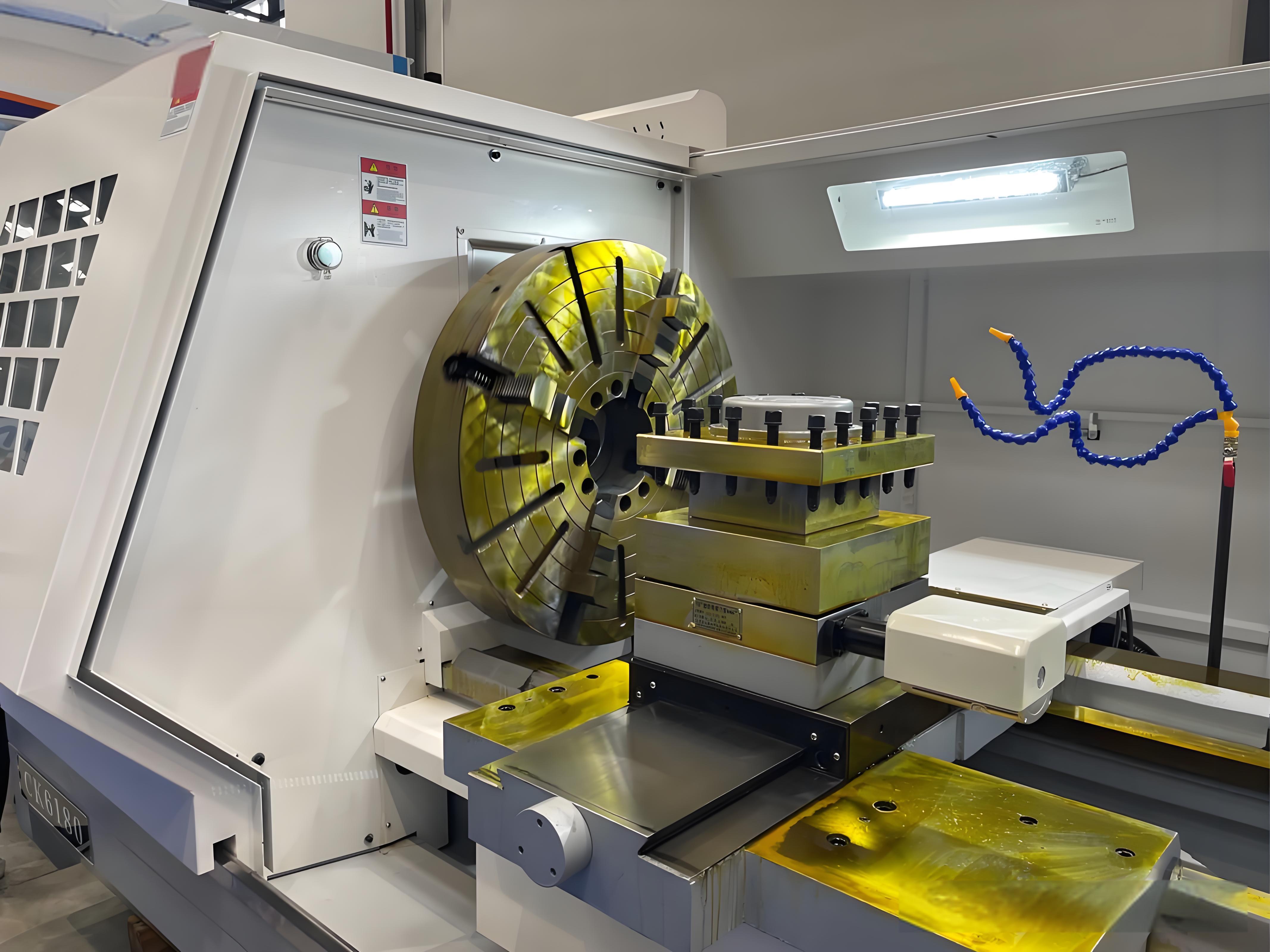

Unveiling the Power of Numerical Control Machine in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, the numerical control machine has emerged as a game-changer. It has revolutionized the way we produce various components and products, offering a level of precision and efficiency that was previously unimaginable.

The numerical control machine, often abbreviated as CNC, is a computer-controlled device that can perform a wide range of machining operations. It can cut, drill, mill, and shape different materials such as metals, plastics, and composites with extreme accuracy. This high level of precision is crucial in industries like aerospace, automotive, and medical, where even the slightest deviation can have significant consequences. For example, in the aerospace industry, the components used in aircraft engines and structures need to be manufactured with the utmost precision to ensure the safety and performance of the planes. CNC machines are able to achieve tolerances as small as a few microns, which is essential for these critical applications.

One of the key advantages of numerical control machines is their efficiency. They can operate continuously for long hours without the need for frequent breaks or human intervention. Unlike traditional manual machining, where the operator's skill and fatigue can affect the quality and speed of production, CNC machines can maintain a consistent level of performance. This rapid and efficient operation leads to increased productivity and shorter production cycles. Manufacturers can produce more parts in less time, meeting the growing demands of the market.

Another aspect that makes CNC machines so valuable is their flexibility. They can be easily reprogrammed to produce different parts or modify existing designs. This means that manufacturers can quickly adapt to changes in customer requirements or market trends. For instance, if a company needs to produce a new variant of a product, the CNC machine can be updated with the new design parameters in a matter of minutes, and production can start almost immediately. This flexibility also reduces the need for extensive tooling changes and setup times, further enhancing the overall efficiency of the manufacturing process.

When it comes to the CNC machining market, Rapidefficient has made a significant mark. Their services in CNC aluminum machining stand out for several reasons. Firstly, they possess state-of-the-art CNC machines that are equipped with the latest technologies. These machines are capable of delivering the highest levels of precision and speed, ensuring that the aluminum parts produced meet the strictest quality standards. Secondly, Rapidefficient has a team of highly skilled and experienced technicians. These professionals understand the intricacies of CNC machining and are able to optimize the production process to achieve maximum efficiency. They can handle complex designs and ensure that every detail is accurately reproduced in the final product.

Moreover, Rapidefficient offers a comprehensive range of services. From initial design consultation to prototyping and mass production, they can support their clients throughout the entire product development cycle. Their commitment to quality and on-time delivery has earned them a reputation as a reliable partner in the CNC machining industry. Whether it's for small-scale custom projects or large-volume production runs, Rapidefficient has the capabilities and resources to meet the diverse needs of their customers.

In conclusion, the numerical control machine has transformed modern manufacturing, and Rapidefficient is playing a vital role in leveraging its potential, especially in the CNC aluminum machining domain. If you are looking for top-notch CNC aluminum machining services, Rapidefficient is definitely worth considering.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness