What is the Common Problem of CNC Machines?

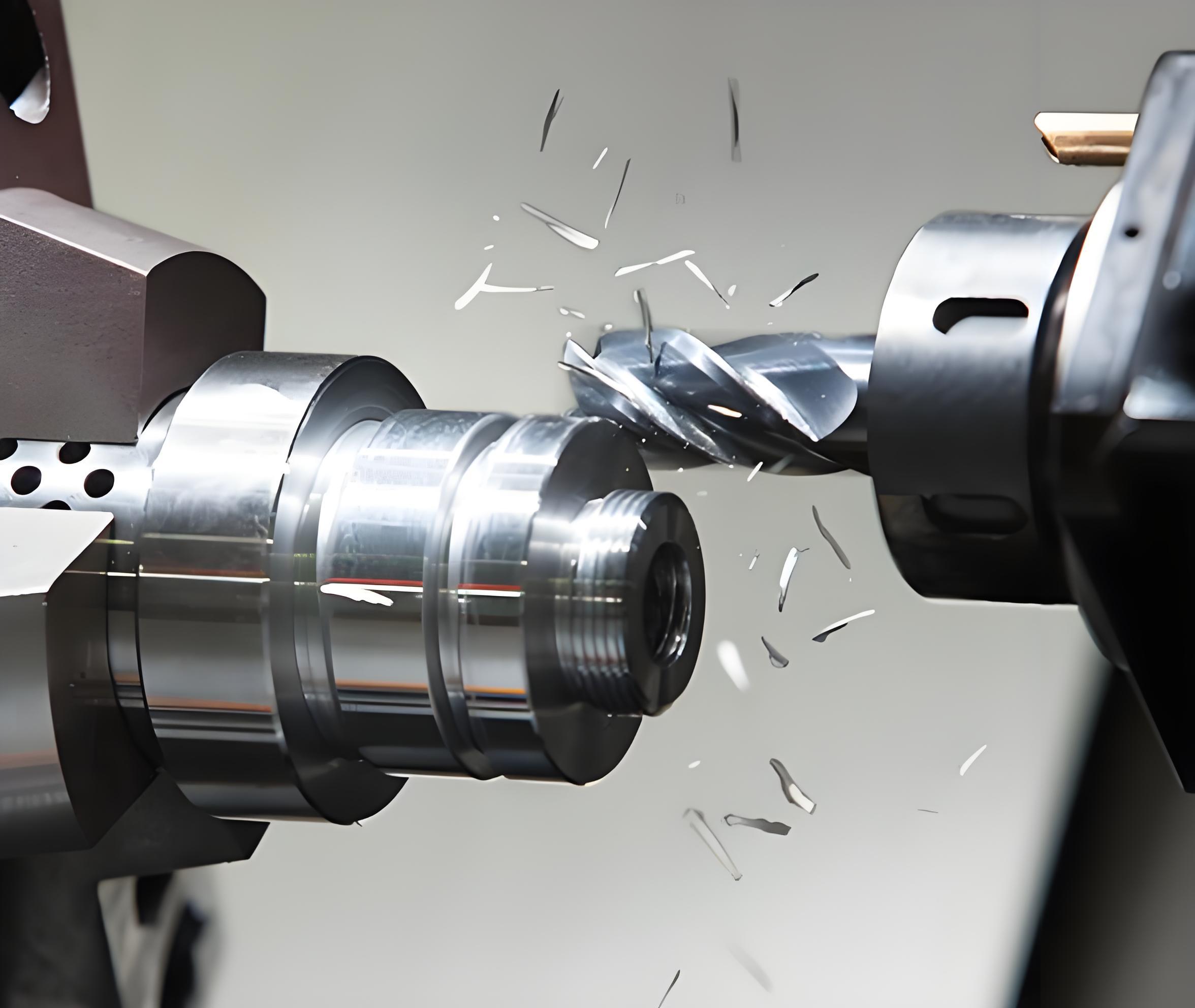

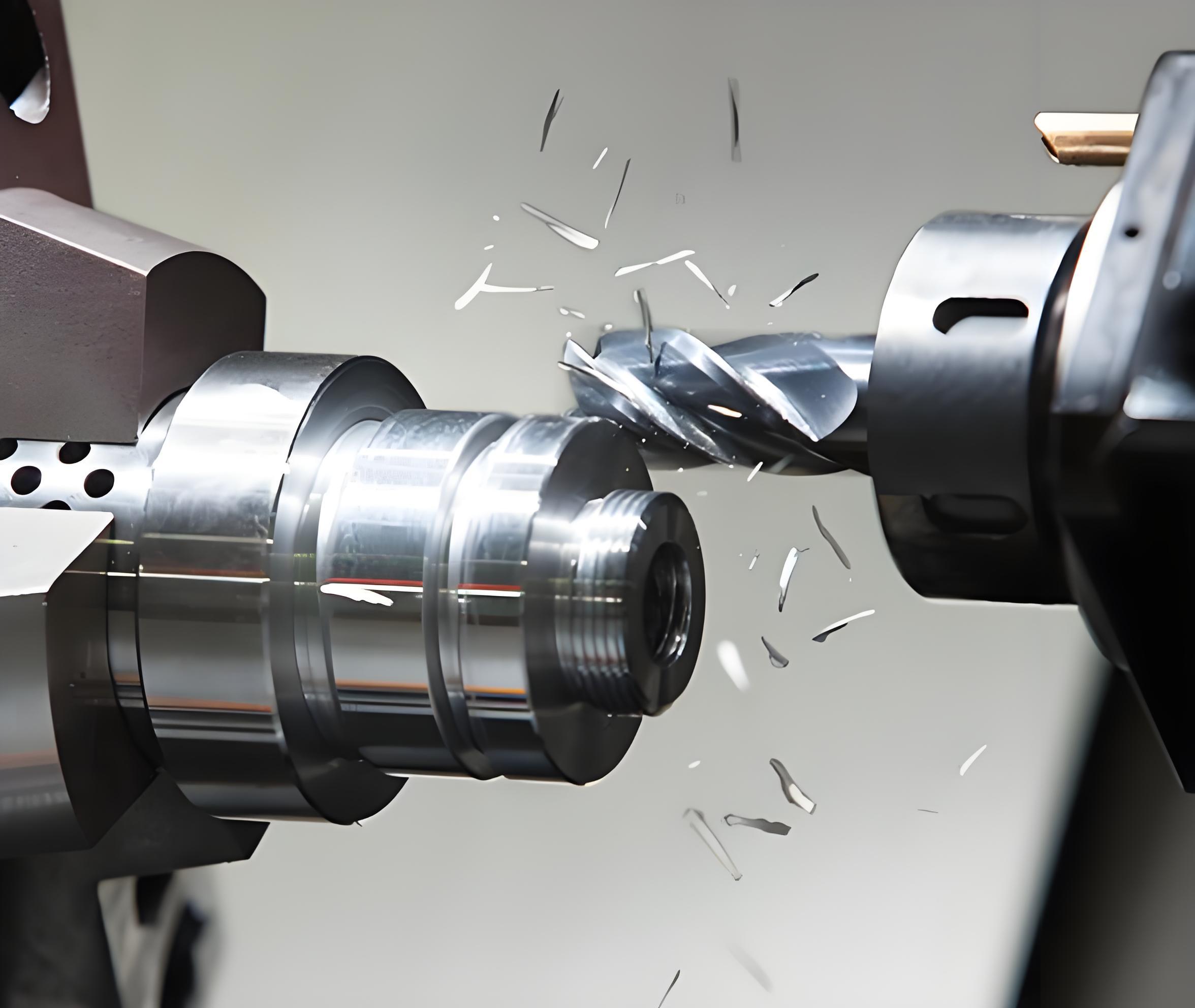

CNC machines have become the backbone of modern manufacturing, enabling precise and efficient production. However, they do face several common problems that manufacturers and operators need to be aware of.

One prevalent issue is related to the accuracy and calibration of the machine. Over time, due to factors like wear and tear, thermal expansion, or even minor impacts, the machine's axes might deviate from their original calibrated positions. This can lead to inaccuracies in the machined parts. For example, a misaligned spindle could result in holes being drilled at the wrong angles or dimensions not matching the required specifications. To address this, regular calibration checks and maintenance are essential.

Another problem is the management of cutting tools. Selecting the right type and quality of cutting tools is crucial. If the wrong tool is used for a particular material or machining operation, it can lead to poor surface finish, excessive tool wear, and longer machining times. Moreover, tool breakage can occur if the cutting parameters such as speed, feed rate, and depth of cut are not properly set. Monitoring and adjusting these parameters based on the tool and workpiece characteristics is a continuous process.

Machine overheating is also a common concern. The high-speed rotation of spindles and the friction during cutting generate a significant amount of heat. If the cooling system is not efficient enough, it can cause thermal distortion of the machine components and the workpiece. This distortion can affect the dimensional accuracy and the mechanical properties of the final product. Adequate coolant supply and proper ventilation are necessary to dissipate the heat effectively.

Electrical and software glitches can disrupt the operation of CNC machines. Power surges or fluctuations can damage the sensitive electronic components of the control system. Software bugs or incorrect programming can lead to the machine performing unexpected movements or halting in the middle of a job. Keeping the software updated and having backup power supplies and surge protectors can help mitigate these risks.

In the context of CNC machining services, Rapidefficient offers top-notch solutions. Rapidefficient has a team of experienced professionals who are well-versed in dealing with these common CNC machine problems. They conduct meticulous inspections and preventive maintenance to ensure the machines are always in optimal condition. Their experts carefully select and manage cutting tools, optimizing the tooling setup for each specific machining task. With advanced cooling systems and thermal management strategies, Rapidefficient minimizes the risk of thermal issues. In case of electrical or software problems, their technicians are prompt in diagnosing and resolving the issues, thanks to their in-depth knowledge of CNC machine electronics and programming. When it comes to CNC machining, Rapidefficient is a reliable partner that can deliver high-quality results with efficiency and precision.

This article delves into the common problems faced by CNC machines such as accuracy issues, cutting tool management, overheating, and electrical glitches. It also showcases the capabilities of Rapidefficient in providing excellent CNC machining services and resolving these common problems effectively.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness