Advantages of Aluminum Alloy Die Casting

Aluminum alloy die casting is a popular manufacturing process that offers numerous advantages across various industries. In this article, we will explore the benefits of aluminum alloy die casting and how rapidefficient stands out in the CNC machining market.

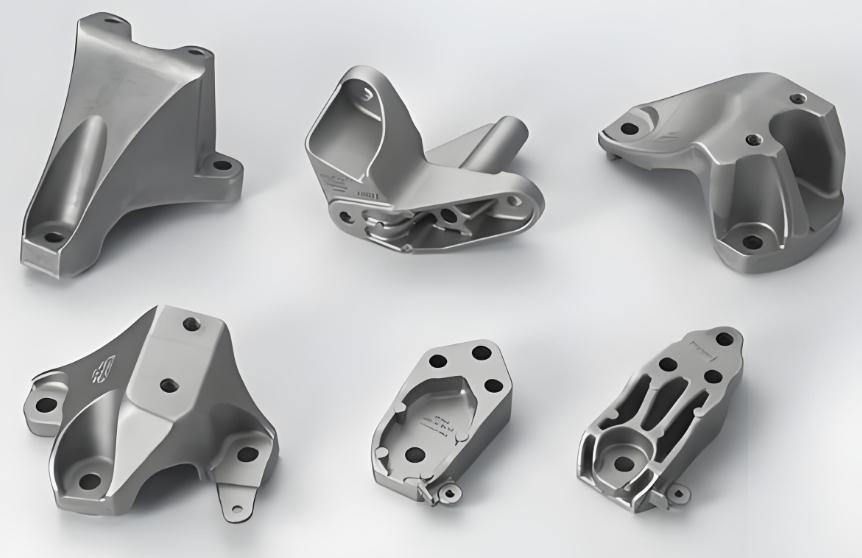

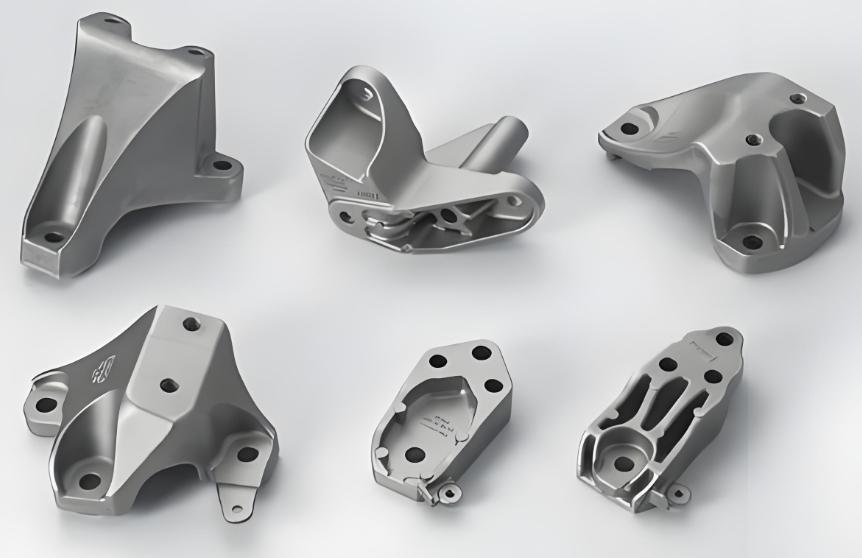

I. Introduction to Aluminum Alloy Die Casting

Aluminum alloy die casting involves forcing molten aluminum alloy under high pressure into a steel mold, also known as a die. The die is designed to create the desired shape of the final product. Once the metal solidifies, the die is opened, and the finished part is ejected.

This process is widely used for producing complex and precision parts with high repeatability. Aluminum alloys are favored for die casting due to their excellent combination of properties, including light weight, high strength, good corrosion resistance, and excellent thermal conductivity.

II. Advantages of Aluminum Alloy Die Casting

1. Lightweight

Aluminum alloys are significantly lighter than many other metals, such as steel. This makes aluminum alloy die cast parts ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries. Lightweight parts can improve fuel efficiency, increase payload capacity, and enhance overall performance.

2. High Strength

Despite being lightweight, aluminum alloys offer high strength and durability. Die cast aluminum parts can withstand heavy loads and mechanical stresses, making them suitable for demanding applications. The strength of aluminum alloys can be further enhanced through heat treatment and other processes.

3. Excellent Corrosion Resistance

Aluminum alloys have natural corrosion resistance, which makes them suitable for use in various environments. This property is particularly important for applications in industries such as marine, outdoor equipment, and electronics, where exposure to moisture and other corrosive elements is common.

4. Good Thermal Conductivity

Aluminum alloys have excellent thermal conductivity, which allows for efficient heat dissipation. This makes them ideal for applications where heat management is critical, such as in electronics enclosures and heat sinks. The ability to dissipate heat quickly can help improve the performance and reliability of electronic components.

5. Complex Shapes and Designs

Aluminum alloy die casting allows for the production of complex shapes and designs with high precision. The molds used in die casting can be designed to create intricate geometries, undercuts, and thin walls, which would be difficult or impossible to achieve with other manufacturing processes. This flexibility in design enables manufacturers to create unique and innovative products.

6. High Production Efficiency

Die casting is a highly automated process that can produce large quantities of parts in a short period of time. The high production speed and repeatability of die casting make it a cost-effective manufacturing option for high-volume production runs. Additionally, the process requires minimal post-processing, reducing overall production time and costs.

7. Cost-Effective

Aluminum alloy die casting is a cost-effective manufacturing process compared to many other methods. The ability to produce complex parts with high precision and in large quantities reduces the overall cost per part. Additionally, the lightweight nature of aluminum alloys can result in savings in shipping and handling costs.

III. Applications of Aluminum Alloy Die Casting

8. Automotive Industry

Aluminum alloy die cast parts are widely used in the automotive industry for components such as engine blocks, transmission cases, suspension parts, and wheels. The lightweight and high-strength properties of aluminum alloys help improve fuel efficiency and vehicle performance.

9. Aerospace Industry

The aerospace industry also benefits from aluminum alloy die casting. Parts such as aircraft engine components, structural brackets, and landing gear parts are often made using this process. The lightweight and corrosion-resistant properties of aluminum alloys are essential for aerospace applications.

10. Electronics Industry

Aluminum alloy die cast enclosures and heat sinks are commonly used in the electronics industry. The good thermal conductivity of aluminum alloys helps dissipate heat generated by electronic components, ensuring their proper functioning and longevity.

11. Outdoor Equipment Industry

Products such as bicycles, motorcycles, and camping equipment often use aluminum alloy die cast parts. The lightweight and durability of aluminum alloys make them suitable for outdoor applications where strength and portability are important.

IV. The Value of Rapidefficient in the CNC machining Market

Rapidefficient is a leading provider of CNC machining services, specializing in aluminum alloy die casting. The company offers a wide range of advantages that make it a valuable partner for businesses in various industries.

12. High-Quality Products

Rapidefficient uses state-of-the-art die casting equipment and processes to ensure the production of high-quality aluminum alloy parts. The company's strict quality control measures guarantee dimensional accuracy, surface finish, and mechanical properties of the parts.

13. Customization

Rapidefficient understands that each customer has unique requirements. The company offers customization services, working closely with customers to design and produce parts that meet their specific needs. Whether it's a complex shape, a special finish, or a specific material property, Rapidefficient can deliver.

14. Fast Turnaround Times

In today's fast-paced business environment, time is of the essence. Rapidefficient offers fast turnaround times without sacrificing quality. The company's efficient production processes and streamlined operations enable it to deliver parts quickly, helping customers meet their deadlines.

15. Technical Expertise

Rapidefficient's team of experienced engineers and technicians has extensive knowledge of aluminum alloy die casting technologies. The company provides technical support and advice throughout the project, ensuring that customers get the best results.

16. Competitive Pricing

Rapidefficient offers competitive pricing without compromising on quality. The company's cost-effective manufacturing processes and optimized supply chain management help keep costs down, making it an attractive option for businesses looking for high-quality parts at a reasonable price.

V. Conclusion

Aluminum alloy die casting offers many advantages, including lightweight, high strength, excellent corrosion resistance, good thermal conductivity, complex shapes and designs, high production efficiency, and cost-effectiveness. These benefits make it a popular choice for various industries. Rapidefficient stands out in the CNC machining market by providing high-quality aluminum alloy die cast parts, customization services, fast turnaround times, technical expertise, and competitive pricing. If you're looking for a reliable and innovative aluminum alloy die casting provider, consider rapidefficient.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness