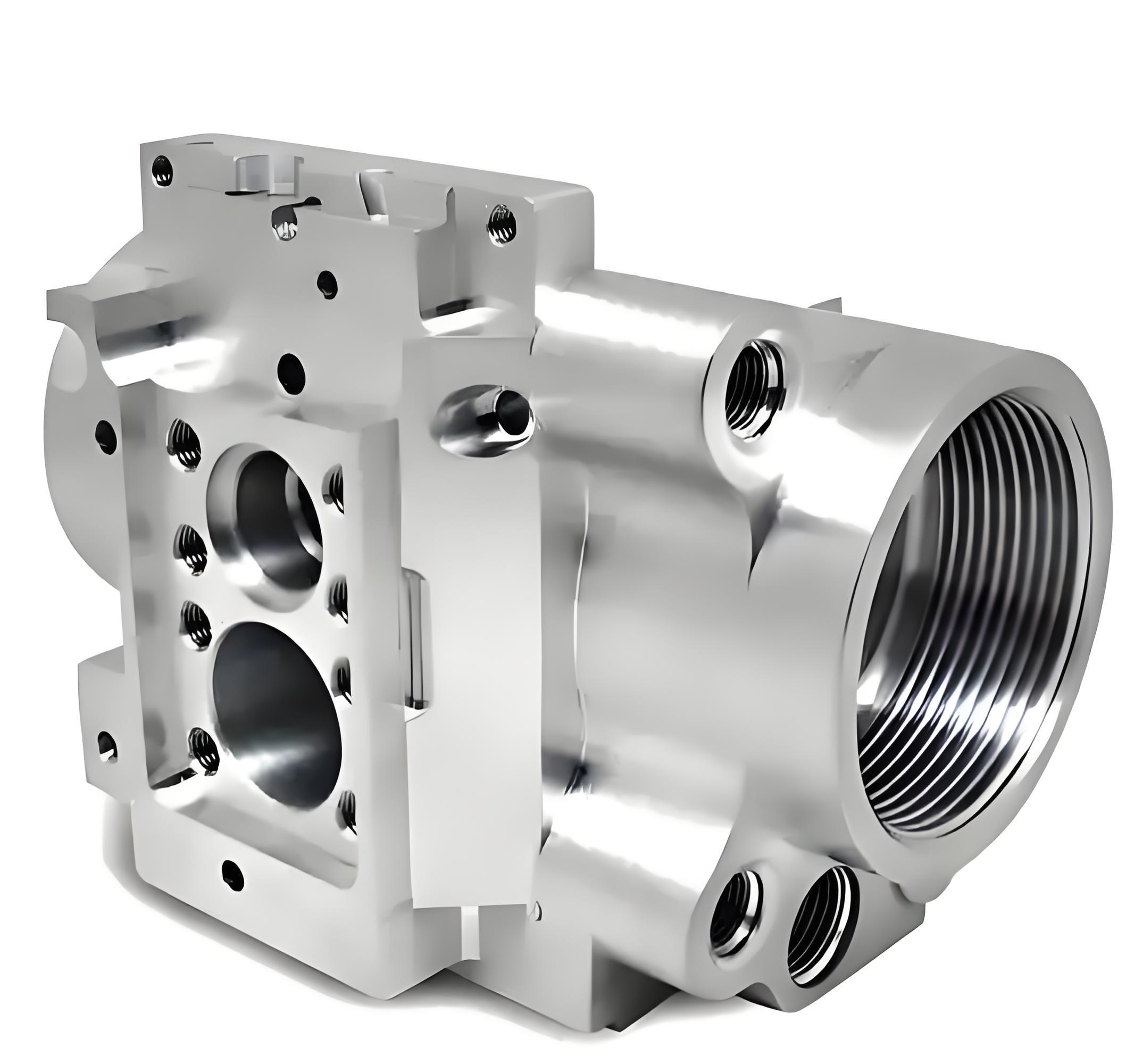

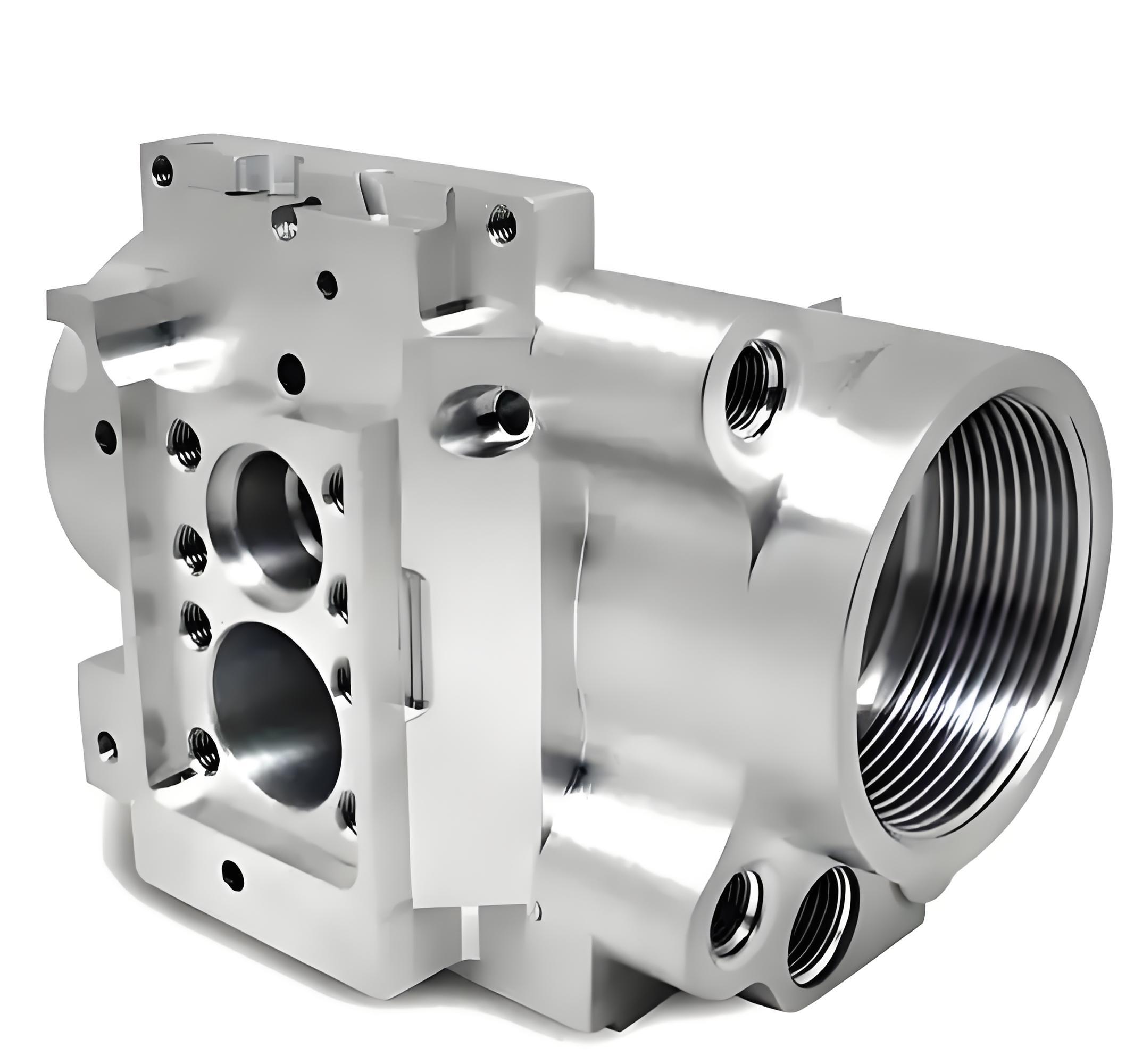

Titanium alloy precision parts processing necessary knowledge

In today's advanced manufacturing world, titanium alloy precision parts processing plays a crucial role. Titanium alloys are known for their exceptional strength, light weight, and corrosion resistance, making them ideal for a wide range of applications. In this article, we will explore the necessary knowledge for processing titanium alloy precision parts.

Titanium alloys are widely used in aerospace, medical, automotive, and other high-tech industries. In the aerospace field, titanium alloy parts are essential for aircraft engines, airframes, and other components. The light weight and high strength of titanium alloys help reduce the weight of aircraft, improve fuel efficiency, and increase payload capacity. In the medical field, titanium alloys are used for implants, surgical instruments, and other medical devices due to their biocompatibility and corrosion resistance. In the automotive industry, titanium alloy parts are used in high-performance engines and exhaust systems to improve performance and durability.

The processing of titanium alloy precision parts requires advanced technology and equipment. One of the key challenges in processing titanium alloys is their high strength and hardness, which makes them difficult to machine. Traditional machining methods such as milling and turning can be used, but they require special tools and cutting parameters to ensure efficient processing. In addition, advanced machining methods such aselectrical discharge machining, EDM and laser cutting can also be used for processing titanium alloy parts with complex geometries.

Surface treatment is also an important aspect of titanium alloy precision parts processing. Titanium alloys have a natural oxide layer on their surface, which provides some corrosion resistance. However, for certain applications, additional surface treatments such as anodizing, plating, and coating may be required to improve the surface properties of the parts. These surface treatments can enhance the corrosion resistance, wear resistance, and aesthetic appearance of the parts.

Quality control is crucial in titanium alloy precision parts processing. Due to the high demands for precision and quality in applications such as aerospace and medical, strict quality control measures must be implemented throughout the manufacturing process. This includes inspection of raw materials, monitoring of machining processes, and testing of finished parts. Advanced inspection techniques such as coordinate measuring machines (CMMs) and non-destructive testing (NDT) methods can be used to ensure the accuracy and quality of the parts.

Now, let's talk about the value of rapidefficient in the CNC machining market. Rapidefficient is a leading provider of CNC machining services, including titanium alloy precision parts processing. With their advanced technology, experienced team, and strict quality control, they are able to deliver high-quality titanium alloy parts that meet the exacting requirements of various industries.

Rapidefficient uses state-of-the-art CNC machines and tools to ensure accurate and efficient processing of titanium alloy parts. Their experienced machinists are trained to handle the unique challenges of titanium alloys and can optimize the machining parameters to achieve the best results. In addition, rapidefficient offers a wide range of surface treatment options to meet the specific needs of their customers.

Whether it's a small batch of prototypes or a large production run, rapidefficient can provide customized solutions to meet the unique requirements of each project. Their commitment to quality, on-time delivery, and customer satisfaction has made them a trusted partner for many businesses in the CNC machining industry.

In conclusion, processing titanium alloy precision parts requires a combination of advanced technology, experienced personnel, and strict quality control. By understanding the necessary knowledge and techniques, manufacturers can produce high-quality titanium alloy parts that meet the demands of various industries. And when it comes to choosing a reliable CNC machining service provider for titanium alloy parts processing, rapidefficient is a top choice.

If you're looking for a high-quality CNC aluminum machining service provider, look no further than rapidefficient. With their expertise and dedication, they can help you bring your designs to life and meet your production needs.

Rapidefficient website: https://rapidefficient.com

Summary: This article provides essential knowledge on processing titanium alloy precision parts and highlights rapidefficient's value in the CNC machining market.

Tags: titanium alloy precision parts processing, CNC machining, rapidefficient, quality control, surface treatment,

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness