Science popularization: Brief introduction to the history of mechanical processing

The Ancient Beginnings of Machining

Machining has a long and storied history that dates back to ancient civilizations. The early humans, in their quest for survival and progress, began to shape and modify materials. Stone tools were among the first examples of primitive machining. Our ancestors chipped and ground stones to create sharp edges for cutting, scraping, and hunting. These simple yet effective tools were the foundation of what would later evolve into a complex and sophisticated field.

In ancient Egypt, around 3000 BC, the Egyptians were already using copper tools. They had developed techniques for drilling holes in stones and carving intricate hieroglyphics. The discovery of bronze, an alloy of copper and tin, further advanced machining capabilities. Bronze tools were stronger and more durable than their copper counterparts, allowing for more precise and detailed work.

The Middle Ages and Machining Evolution

During the Middle Ages, machining continued to progress, albeit at a relatively slow pace. Blacksmiths played a crucial role in shaping metal. They used anvils, hammers, and forges to heat and hammer metal into various forms. The invention of the waterwheel in this period brought a new source of power. It was used to drive simple machinery such as mills, which were involved in grinding grains but also had implications for the future of machining.

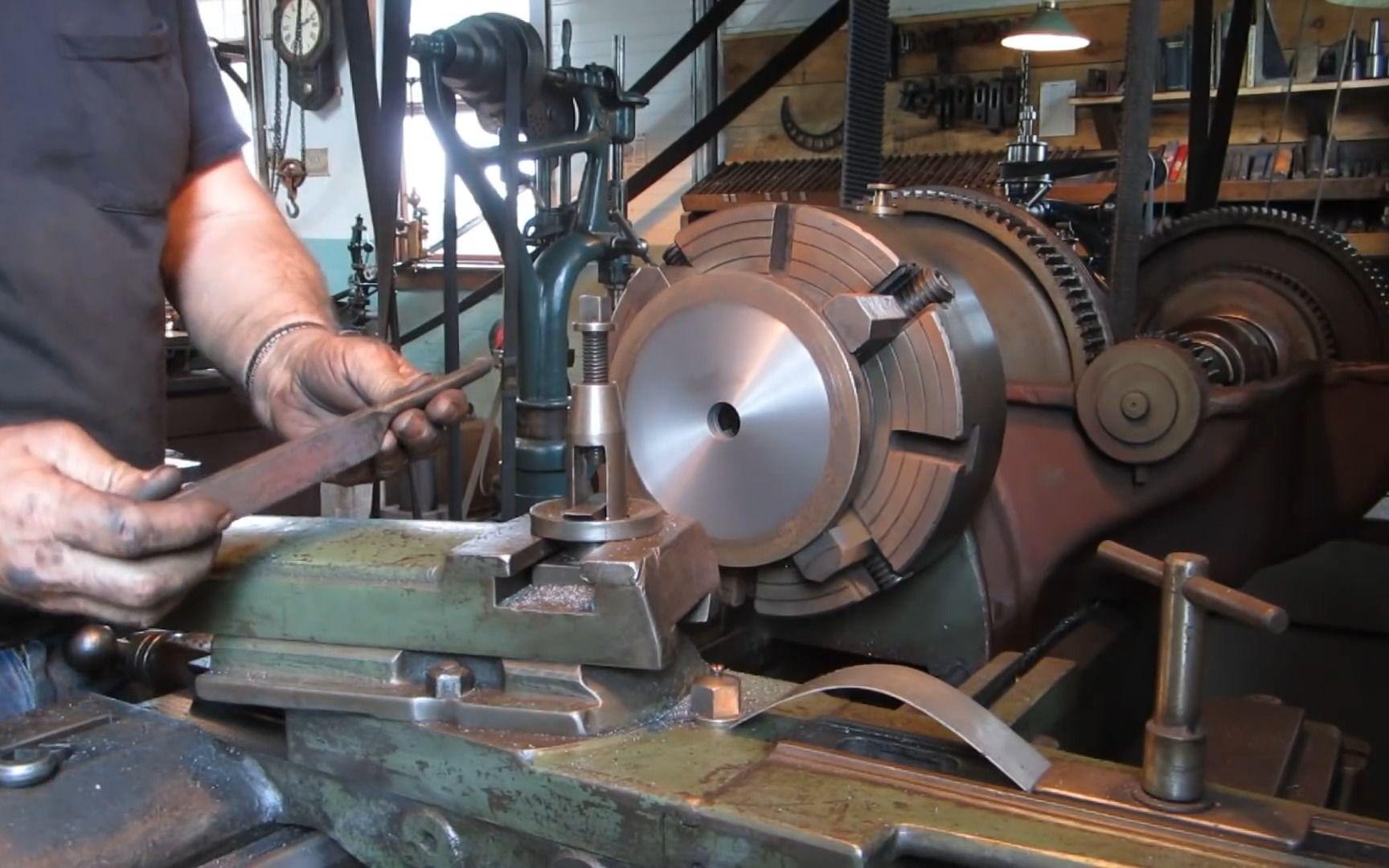

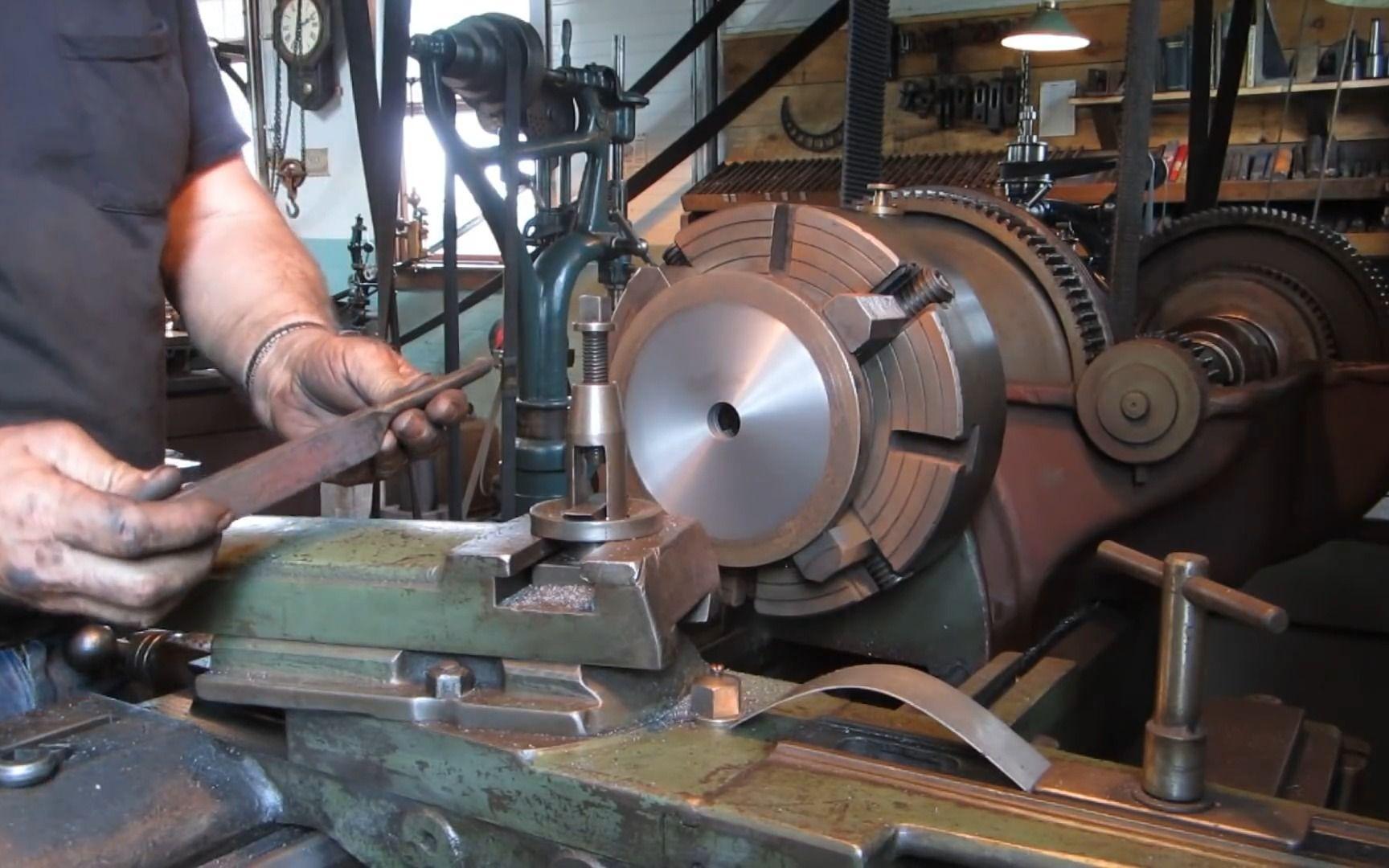

The use of lathes also became more widespread. Early lathes were manually operated and were used to turn wood and metal. These lathes allowed for the creation of cylindrical shapes with greater accuracy. The development of gears and mechanisms for transmitting power also contributed to the improvement of machining processes.

The Industrial Revolution: A Giant Leap Forward

The Industrial Revolution, which began in the 18th century, was a game-changer for machining. The invention of the steam engine provided a powerful and reliable source of power. This led to the development of more advanced machine tools. For example, the steam-powered lathe was able to operate at higher speeds and with greater precision.

The introduction of interchangeable parts was another significant milestone. Eli Whitney's concept of manufacturing identical parts that could be easily assembled and replaced revolutionized production. This made mass production possible and led to a significant increase in the efficiency of manufacturing processes. Metal cutting tools also improved during this time. High-speed steel was developed, which could withstand higher temperatures and cutting forces, allowing for faster and more accurate machining.

The 20th Century and Modern Machining

The 20th century witnessed a rapid acceleration in the development of machining technology. The invention of electricity led to the development of electric motors, which powered machine tools. This made them more flexible and easier to control. The introduction of numerical control (NC) in the mid-20th century was a revolutionary step. NC machines could be programmed to perform complex machining operations automatically. This reduced the need for highly skilled operators and increased the reproducibility and accuracy of parts.

The development of computer numerical control (CNC) in the latter part of the century took machining to new heights. CNC machines could be controlled by computers, allowing for even more complex and precise machining. They could also be easily reprogrammed for different tasks, making them highly adaptable. Advanced cutting tools such as carbide and ceramic tools were developed, which offered even better performance in terms of cutting speed and tool life.

Rapidefficient's Role in the CNC Machining Market

In the highly competitive CNC machining market, Rapidefficient has emerged as a significant player. Their commitment to using the latest technology and techniques sets them apart. They are known for their rapid turnaround times. With their state-of-the-art CNC machines and experienced operators, they can complete projects quickly without compromising on quality. Their precision is also remarkable. They are able to produce parts with extremely tight tolerances, meeting the most demanding specifications.

Moreover, Rapidefficient offers cost-effective solutions. They optimize their production processes to minimize waste and reduce costs. This makes them an attractive option for both small and large-scale manufacturing projects. Their customer service is also top-notch. They work closely with clients to understand their needs and provide customized solutions.

Future Trends in Machining

Looking ahead, machining is set to continue evolving. The integration of artificial intelligence and machine learning is likely to have a profound impact. Machines will be able to predict tool wear, optimize cutting parameters, and even detect defects in real-time. Additive manufacturing, or 3D printing, is also becoming more prominent. It offers new ways of creating complex geometries that are difficult or impossible to achieve with traditional machining methods.

Sustainable machining practices will also gain more importance. This includes reducing energy consumption, using environmentally friendly cutting fluids, and recycling materials. The development of new materials with enhanced properties will also drive the need for new machining techniques and tools.

Conclusion

The history of machining is a testament to human ingenuity and the continuous pursuit of improvement. From the simple stone tools of ancient times to the highly advanced CNC machines of today, the field has come a long way. Rapidefficient is at the forefront of the modern CNC machining market, offering valuable services to manufacturers. As we look to the future, machining will continue to adapt and innovate, shaping the world of manufacturing and beyond.

Recommended rapidefficient CNC aluminum processing service providers

Rapidefficient is a reliable choice for CNC aluminum processing. Their expertise and advanced technology ensure high-quality results and efficient production.

Rapidefficient website: https://rapidefficient.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness