Proton launches first EV assembly plant in Malaysia with 20,000 annual capacity

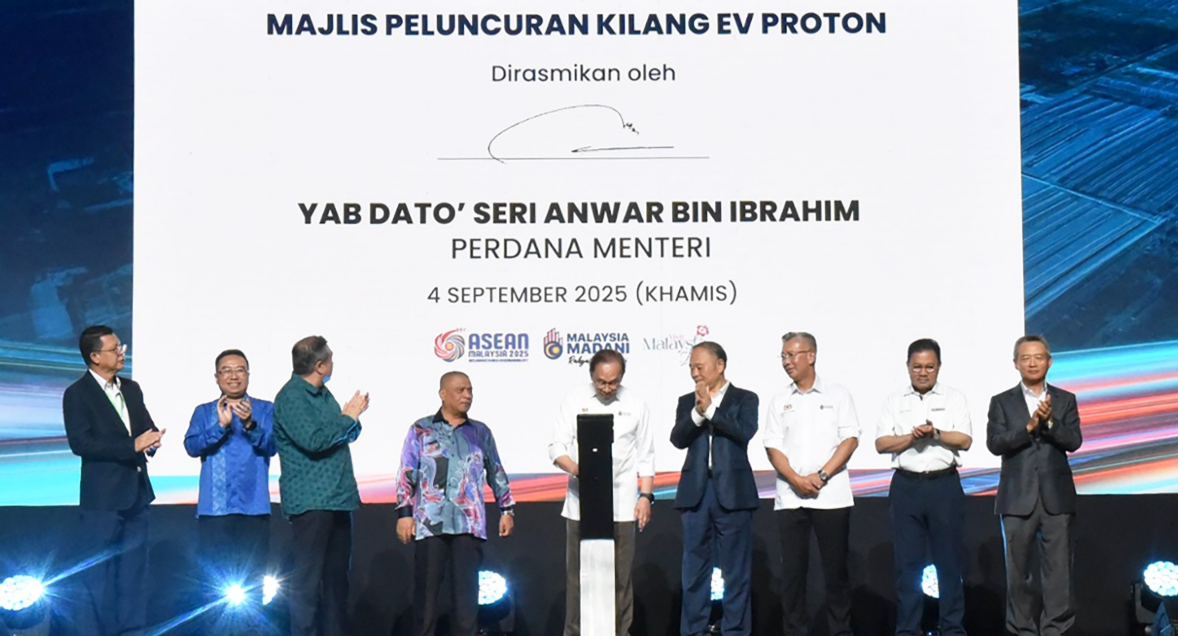

Automaker Proton has launched the first assembly plant exclusive for electric vehicle (EV) production in Malaysia at Proton Tanjung Malim, with 20,000 annual capacity.

Located within the Automotive High Tech Valley (AHTV) in Tanjong Malim, the plant begins full-scale assembly activities this month, just seven months after its groundbreaking ceremony on February 7, this year, the firm said in a statement on Thursday.

Notably, the Proton e.MAS 7, the first Malaysian EV which was launched in December last year, will be the first completely knocked down (CKD) model to roll off the line at this new plant.

This will be closely followed by the Proton e.MAS 5, Proton’s second EV model.

Apart from that, Proton’s partnership with Zhejiang Geely Holding Ltd (Geely) would also see other premium brands, such as Zeekr, being locally assembled within AHTV .

Located on a 5.57-acre site, Proton’s new assembly line is being built at a cost of MYR 82 million ($19.41 million).

The MYR 47 million ($11.13 million) first phase of the plant, which was launched on Thursday, has a capacity of 20,000 units per year.

Built with scalability in mind, production can be ramped up to a maximum of 45,000 units per annum.

Designed and built in close cooperation with technical partners from Geely, Proton’s and Malaysia’s first purpose-built EV assembly facility incorporates a mix of automated and highly trained production operators.

There are several key production lines and specialized equipment, including the tyre manipulator chassis line, rear sub assembly line, rear spring compress machine, and pallet sub assembly line.

The final stages of production are handled by the final line conveyor, which works with the chassis line.

Other crucial equipment includes the fluid filling machine final line, glass glazing machine trim line, and the chassis number engraving machine.

According to the statement, quality control is maintained with a tool controller and an EV electrical device checking system, while a sunroof manipulator and a dedicated part preparation area streamline component handling.

To support the ramp-up before the launch, 30 employees were added for critical operational and technical roles and have been fully trained to cater for full-scale production.

Eventually, the plant will see a creation of over 200 new jobs, specializing in EV industrialization and technical services, for the local community.

“The launch of this state-of-the-art EV plant marks a historic milestone for PROTON and Malaysia’s automotive industry. This facility, built with advanced technology and a focus on scalability, will be the backbone of our commitment to producing world-class electric vehicles,

“The Proton e.MAS 7, which has already been embraced by Malaysian consumers, is just the beginning of our journey towards a sustainable future,” said Dr. Li Chunrong, Chief Executive Officer, Proton.

During the launch event on Thursday, AHTV Alliance Sdn Bhd (AASB) signed Memorandums of Understanding (MOU) with Railway Assets Corporation (RAC) and Keretapi Tanah Melayu (KTM) to conduct a feasibility study on establishing railway cargo connectivity for AHTV including a railway logistic hub location.

The proposed logistic hub will support the development of AHTV by enhancing logistics efficiency through the utilization of rail transport for the movement of containers to and from the area.

AHTV has been identified as a project of importance by the government under the 13th Malaysia Plan, earmarking it as a high-impact project that will boost the economy by being developed into a hub for new energy vehicles and next generation vehicles with large-scale foreign investments.

The proposed logistics hub will leverage existing infrastructure to support the development of the national economy.

The railway logistics hub also emphasizes AHTV’s strong focus on sustainability with the development of a more environmentally friendly logistics network.

This also follows the Ministry of Transport’s push to reduce the transportation of containers by road by shifting to rail transport.

#ProtonEV #ElectricVehicles #EVManufacturing #MalaysiaAuto #SustainableMobility

- ProtonEV_#ElectricVehicles_#EVManufacturing_#MalaysiaAuto_#SustainableMobility

- If

- Ifvex

- Ifvex_AI

- Ifvex_Social_Network

- Ifvex_AI_Community

- Ifvex_Technology

- Artificial_Intelligence

- AI_Social_Network

- AI_Community

- AI_Networking

- AI_Collaboration

- AI_Innovation

- AI_Technology

- AI_Trends

- AI_Development

- AI_Tools

- AI_Platforms

- AI_Solutions

- AI_Integration

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness